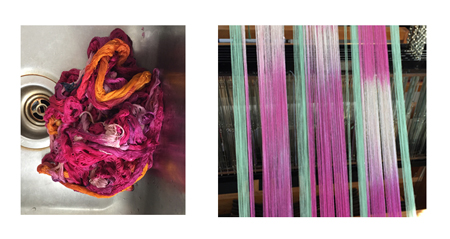

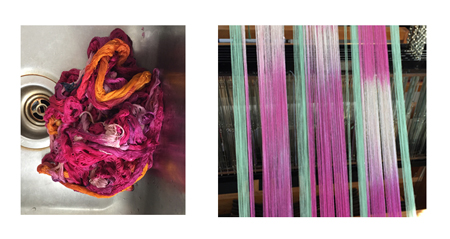

You may have been curious about that last batch of hand painted silk. In the sink you saw that there was yellow in the warp, but in the photo of it being beamed, there was no yellow. What you saw being beamed was the first section I painted, before I added yellow to the mix of colors. Did I mention that I didn’t really measure where I was on the warp when I made that decision? It was a guesstimate. I knew that as I was weaving I might determine that I didn’t guess very well…only time would tell.

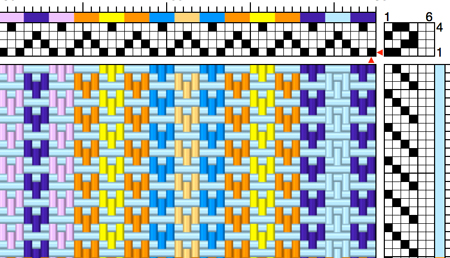

Anyway, I wove the first scarf using a very dark purple weft, in what I call a ‘leaves’ threading and treadling. In this view you can see both sides of the scarf, and see how the purple comes to the foreground or retreats a bit.

For the second scarf I previewed a few different weft colors, deciding I liked ruby best. I used three strands of ruby tram silk. Tram is the very shiny, super fine silk they used in making kimono. Using three strands together was still finer than the silk in my warp. I kept the same tie up but changed the treadling to a network twill. I’d used this treadling for the hand painted rayon shawls I made a month or two ago.

Although it was more tedious and time consuming to weave with the 3 strands, I loved the way the scarf was turning out. I was merrily weaving along, and oops…before I got to the length I wanted I hit the place where the yellow ended. I decided it would be better to have a scarf that’s 10″ shorter than my usual length than to suddenly stop having yellow in the warp.

So I previewed a few more weft colors for this last section, the scarf with no yellow in it. I thought I’d use a gold, yellow, or salmon weft, but when I tried them out none tickled my fancy. Instead I chose periwinkle, which happens to be one of my go-to colors. I went back to the treadling for the leaves.

Once again you can see how significantly the choice of weft color impacted the overall look of the three scarves, not considering the loss of yellow in the third. I am learning more about color interaction since I started doing hand painting than I did in the several previous years. Who knew that would be such a nice surprise?

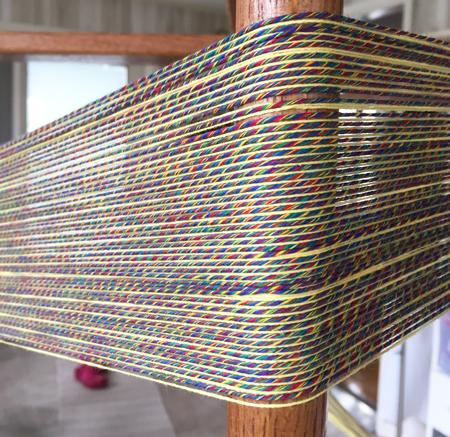

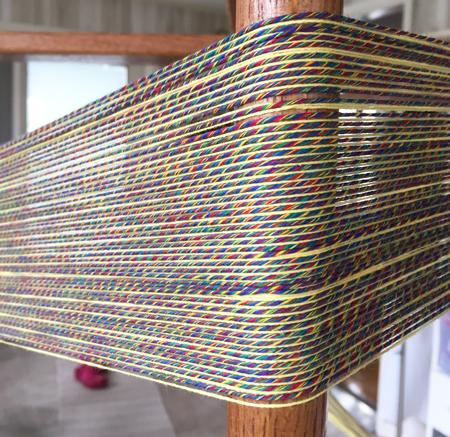

Now I needed to get back to a little stash busting. I found some of what I’ll call confetti colored yarn, in a blend of cotton, rayon and linen in my stash. I paired it with some solid yellow cotton, and measured the threads out for a log cabin weave.

I don’t know if I’ll like it or hate it, but it will probably be one of those two, nothing in between. In addition to the overall colors, the confetti yarn is a thicker grist than the yellow cotton, and that may make it cool to look at or awful. Again, only time will tell.

I only had enough of each of the yarn for three towels, so that’s what I measured for. I won’t have time to get it on the loom till I come back from Cazenovia. Once I start weaving if I really hate it, I can just cut it all off and throw it away. As one of my weaving gurus, Laura Fry, says, it’s much more cost effective to throw away some yarn than to waste a bunch of time. (Certainly my paraphrasing; Laura wording is much better.) Stay tuned to see what it looks like.