The sample wrap is winging its way to California for my three ‘professional’ moms to test out with their little ones. I can’t wait to hear what they have to say!

|

||||||

|

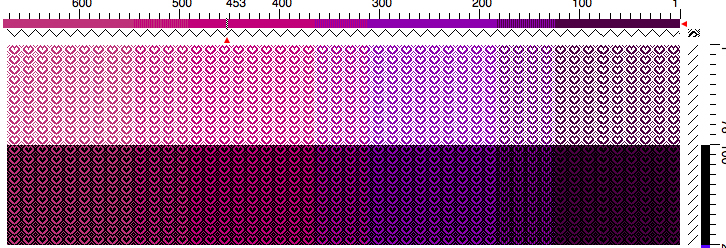

As planned, I’m weaving a full size wrap, using Meghan’s colors with a cream weft. When it’s done I’ll cut it off the loom, hem and wet finish it, and send it to Meghan for her and two other moms to test out. They’ll each use it for a week, write down their comments, and send it back to me. I’ll use their input to determine if I need to make any adjustments before proceeding. So after getting the loom threaded I sat down to throwing the shuttle. I had only one tiny threading error, which I fixed relatively easily. I timed myself at several different times to see how many inches of baby wrap I can weave in 15 minutes. The clear answer is 7 inches. Despite needing to wind bobbins and fix a broken warp thread, my time didn’t vary much at all. Here’s what I originally wrote in the draft of this post: “It’ll be fun to take all my measurements: width in reed, width on loom, length on loom, width and length off loom, width and length after wet finishing. All this info is critical to me knowing how I have to plan future wraps to make sure I can produce wraps in the promised sizes.” Hah, HAH, HAH! I finished the weaving last night and cut it off the loom today, taking care to reinsert lease sticks and have enough length in front of the reed so all I have to do is tie to the apron rod to start the second warp, assuming no changes are needed. In good weaving practice, the first thing I did after it was off the loom was to measure the width & length. WHAT??!!! I wove 205″ on the loom, under tension. How can it POSSIBLY be 225″ off the loom?? I marked my weaving length by inserting safety pins, just like always. The only difference is that I used 20″ for my distance between pins instead of my usual 10″. Count the pins again – 10. 10 pins x 20″ = 200″. Measure the cloth again – 225″. Go over the edge of the cloth again to make sure I didn’t miss a pin. Nope. Measure the cloth again – 225″. Scratch my head, sit down and look at the fabric. Measure the cloth again, this time in yards instead of 50″ increments- still 225″. What the heck??!! How is this possible?! Walk away. Chop veggies for soup. DOH! (Heel of palm to forehead.) I know how it happened! Usually when I’m weaving a scarf, I use 1 less pin than needed. So if I want to weave 76″ of length, I use 6 pins, each 10″ apart, and don’t use a pin for that last 16″. But I used 10 pins, each 20″ apart, and THEN did my last 25″. I should have used 9 pins, not 10. CRAP!! Now will I have enough length to weave the second warp the length Meghan wants? Go to my worksheet and do some quick calculations. WHEW!! I should have plenty, with a bunch left over. For my first baby wrap, I made my warp extra long, just to make sure I didn’t cut myself short. The lesson to be learned here: follow your usual process! Now I’m going to email my test mammas and see if I should hem the extra long wrap as is, or cut 20″ off it first. It took FOREVER to beam the warp for Meghan’s baby wrap. Honestly, although I said I was going to keep track of the time spent, I stopped doing so after 3 1/2 hours when I felt very far from the end of the beaming process. I kept being interrupted – by phone calls, by needing to make soup, to rest my body, to refill my patience store – but I know I spent at least another 3 hours, probably quite a bit more. I also know that I made some mistakes in my process (like compressing the threads in the raddle to 40 EPI so I could use my favorite lease sticks) that I will correct next time. So I’m writing the beaming down on my paper as 6+ hours. The next step was threading 940 heddles. Honestly, I used to dislike this step of the weaving process but I don’t now. After the challenging of beaming, I was actually looking forward to something that was merely tedious & time consuming, something that wouldn’t challenge my brain or my body. I got all heddles threaded, hopefully without error, in 4 hours. I’m doing a simple point twill threading, so after each group of 14 threads (threaded 8-7-6-5-4-3-2-1-2-3-4-5-6-7) I checked the threading of that group before tying my slip knot and proceeding. It’s not guaranteed that I have no heddle threading errors, but it’s not overly likely. If I can be as careful in threading the reed (where I usually make my errors), it’ll be good. I’d LOVE to get the loom all threaded, tied up, and the header woven before the day’s out. That’s when I’ll know for sure if I’ve got any threading errors. I know moms are waiting to see how this warp progresses, too, since this is the first of several orders I have for baby wraps. The fuchsia yarn arrived and I can get started on the baby wraps – finally! Last night I measured two bouts on the new-to-me warping mill. First came the darkest color – dark mauve. The warping mill is much quicker than measuring on the warping board, but it still wasn’t quick. This first bout of 196 threads took me 1 1/2 hours to measure. Longer than I thought. Ditto with the second bout. Then I was done for the night. This morning I started measuring more of the warp, and it went faster. I could wind a bout in much closer to an hour. Whew. That feels better. It’s fun to see the warp take shape. Here’s light mauve, the blended section, and then the fuchsia. Doesn’t it look yummy? After I got all 940 ends measured (almost 7 hours), I took it over to the loom and spread it out in my raddle. That took about 45 minutes. Usually I spread the warp on the back beam to the exact width it will be in the reed. This time I decided not to spread it that far, as it would present me other problems – I’d have to use lease sticks I don’t like, they wouldn’t fit through the chains on the Macomber to move to the front of the loom, and therefore I would have plenty of problems trying to use my warping valet. The next step is beaming that warp – winding the yarn on the back beam, being very careful to maintain tension throughout the process. I worked on it for about an hour and then was done for the night. Tomorrow I’ll finish beaming and start the threading. I am definitely keeping track of my time to so I can determine if the prices I’m charging are reasonable or need to be adjusted for people I haven’t quoted yet. Surely you learned about the poet Robert Burns in school. Those plans ‘gang aft agley.’ Once again, my plans went awry. After finishing that last post I went first to my notes and computer, writing down how many threads of each color I needed to measure in what order for that first baby wrap.

POOP!! There’s a mistake and I’m missing the 3 cones of fuchsia! I ordered it, was invoiced for it, but didn’t receive it. A phone call to the friendly customer service rep confirmed that they’d made an order and would send me out the missing yarn, but that meant I had to wait. Despite what everyone who sees me weaving in a demo at a show says, I don’t think I’m a patient person. I’m definitely bad at waiting. No control, no choice. The good news is that after pouting a bit and notifying my first few customers that this would delay orders by a week, I found something good to do with my time. I started writing the narrative for a grant application that’s due in 2 weeks. Remember that community weaving project? I’m planning a modification of it, working with my local library and elementary school. I have no idea if I’ll get funded, but I surely won’t if I don’t get it written and submitted! I made a good start on it that day, and I’ll work on it more tomorrow, hopefully getting it finished in the next few days so that once that yarn arrives the application will already by submitted. That’s the plan, at least. 😉 |

||||||

|

Copyright © 2025 Weaving A Gem Of A Life - All Rights Reserved Powered by WordPress & Atahualpa |

||||||