|

|

I don’t know about you, but for, talking about an issue helps me think things through & sometimes to solidify my thoughts, come up with the answer I couldn’t find silently. So I have long-suffering friends who are patient as I babble on.

When I was talking to Margaret, a non-weaver, about my loom decision challenge, she told me I would know when I had the answer, that it would become clear to me. I wasn’t so sure, and told her so.

Days passed with no clarity.

And then on my morning walk, suddenly I realized I did know which loom I would sell. It would be the Varpa. This became clear to me only when I realized that, thanks to the folks at Weavolution, I had several possible solutions to the problem of the Mac pulling the weft apart, and I was willing to try any or all of them. Based on other people’s experiences, I had no doubt that one of would solve my problem. But that wasn’t really what made that little bell go off in my head — it was the fact that I was willing to try everything from newspaper and saran wrap to aluminum beam covers, replacing the breast beam to sanding and oiling. If I was willing to put this time, energy, and maybe money into it, it must mean I wanted to keep it.

So I said to myself, “I’ll sell the Varpa.” That felt ok. Then later on I said it over the phone to Margaret. That felt fine, too. No second guessing. It was clear.

Yesterday I took a mess of pictures of it and the accessories that would go with it. I pulled out my receipts for the loom, the books, and the Texsolv I had to purchase for it and added them all up. Then I posted it for sale with four guilds in the region. Figured that sometime this weekend I’d post it on Weavolution, Ravelry, & CraigsList.

Hah!

Within a few hours I got an email from a man who’s interested. This morning we spoke on the phone, and he’ll come in a few days to check it out and be certain it’s what he wants, but he’s pretty confident that it is.

I will not make a profit on this loom. In fact, I’ll be eating the cost of the van rental I needed to pick it up. (Well, not totally eating it; I will claim the cost on my income taxes.) But I still feel fine about it. Not one whit of seller’s remorse — another clue that this is the right decision for me.

Once it’s gone I’ll get the dining room table back in the house. Then I’ll just focus on what I need to do for a bit. If I’m supposed to get another loom, it will have to find me instead of the other way around. (Actually, I’d kind of like to have a small-ish folding floor loom I could put in the back of my little car & use for demos, if you know/hear of anyone getting rid of one cheap.)

So for now I’m weaving on my sweet, little counterbalance. I’ll put a warp on the Mac as soon as I’ve finished the first attempted fix.

I feel good about it all.

I did what I planned, and wove the exact same pattern, exact same fiber, exact same sett on both the Varpapuu & the Macomber to determine which loom I would keep and which I would sell.

Here’s what I learned — I still don’t know.

Each loom had a warp long enough for two scarves. First I wove scarf #1 on the Varpa. It was fine. I was sure I’d like it better than the Mac. Instead of weaving both on the Varpa & then both on the Mac, I thought it would be best if I did one scarf on each. So I went to the Mac for scarf #1 there.

What?! I was shocked that I thought I liked weaving on the Mac better! That was so not what I was expecting; I had sort of set the Mac up to fail, but it didn’t. What the heck did that mean?

So I went back to the Varpa for scarf #2 there. Again, I liked it. Each loom has its pluses & minuses. Maybe I should identify what I like and dislike about each.

Varpa pluses

- I love the way the brake works

- I like that I can expand it to 12 harnesses with minimal cost

- The loom itself is a thing of beauty

- I love how quiet it is when I’m weaving

- I like the knee beam

Varpa minuses

- I don’t like the fact that it takes up an entire room; I thought I’d want a loom that could weave 48″, but since having one in the house, decided it’s not important to me

- Because it’s so wide, I can’t really reach the brake and set the tension while I’m seated; I have to get up every time

- While I don’t mind the weight of the beater as I’m weaving (much heavier than the beater on my Mac or my counterbalance) I wonder about the long term impact on my back, shoulders, neck, and arms

- I don’t like the fact that it only has 8 treadles; yes, I could have 2 more made by a woodworker, but that’s an additional expense. Â Plus, if I want to expand to 12 harnesses I’d want 14 treadles, and I don’t know that there’s room for that in the loom construction

- I don’t like the ‘floating’ treadles, nor how little space there is between them; yes, I could have a treadle gate made, but again, that’s an additional expense

- I timed it – it took me 45 minutes to do the tie up; that’s a long time for each setup

Mac pluses

- I like the foot rest bar – it’s a brilliant design feature

- I like the amount of space between the treadles – it’s easy to find the correct one

- I like that I could expand it to 10 harnesses & 12 treadles if I want to

- I like that the tieup is quick – just under 15 minutes

- I like that it fits in my space well – a fairly small footprint for its capacity

- I like the fact that I can release the brake and set the tension from my seat

Mac minuses

- I don’t like how noisy it is

- I don’t like the fact that sometimes the harnesses stick in the up position, or that the treadle clips sometimes pop off

- I wish it could weave to 36″ wide instead of its 32″ capacity

- Biggest minus of all – the Mac has a habit of separating my weft as it goes over the breast beam. Â I had thought it was me, that there was something I was doing wrong – particularly that I was leaning against the finished fabric as it was on the breast beam causing the problem. Â This time I paid particular attention, and made certain I didn’t do that. Â But the problem occurred anyway. Â Yet only on the Mac, not the Varpa, so it is obviously a Mac problem.

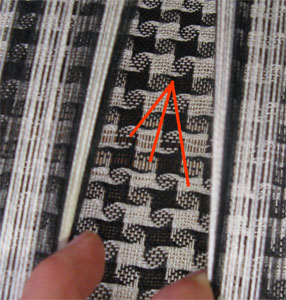

Here’s a shot of the fabric before it goes over the breast beam…

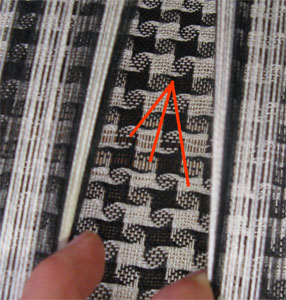

…and here’s what it looks like after it passes over the breast beam. Note the red lines, pointing to where it has separated or crammed that weft.

Fortunately those problems came out in the wet finishing – this time; they haven’t always. Â Ultimately, if I can’t weave the kind of cloth I want to on the Mac, the decision is made, regardless of its other positive attributes.

So I went to Weavolution & asked if others had had this problem on a Mac, & if so, how they resolved it. I got some great answers, and I’m working on implementation. After I get done I’ll try another warp of two rayon scarves sett at 18 end per inch and see if it the problem is gone. If so, I believe I’ll sell the Varpa. If not, there’s one more fix to try before I say goodbye to the Mac.

Unfortunately, I have to work quickly to make this decision. My dining room table is out on the porch under a tarp to make room for the Varpa. That’s fine until the snow flies, which will come before I want it to. So, much as I’d like to really take my time and be certain, in addition to not being pressured while I’m preparing for shows, I don’t have the luxury of time.

I’ve decided I can’t yet decide.

But that’s okay, because I came up with a plan that’ll help me decide.

What the heck do I need to decide?

Whether to sell my Macomber or my Varpapuu loom. One of them needs to go. I’ve had the Mac for a handful of years, the Varpa for a few weeks. When I bought the Varpa my hope/plan was that I’d fall in love and sell the Mac in a heartbeat. Now, understanding that I’ll need to make a few modifications to the Varpa to make it fit me better, I’m wondering why I never made mods to the Mac. And I’m thinking that I should try some temporary mods (as I am with the Varpa) before I decide which loom to sell.

So my plan is that I’ll weave 2 scarves of the same fiber, same weave pattern, same sett on each of those looms. I’ll be paying attention to the weaving process while I’m at the loom, and the finished product when it’s off.

I wound a black & white rayon warp, beamed it on the Varpa, and set off weaving an 8 harness pattern.

This is not a quick scarf to weave. I forget how much longer it takes to weave with 2 colors. I’m sure I’ll get into the rhythm once I get going, but it’s never as fast as 1 color. Plus, because I have relatively long floats, I’m using a floating selvedge, which also slows things down, but nowhere near as much as the 2 shuttles.

I am pleased with myself that I planned well enough so that I’m only carrying the white up the side with the white and the black up that side.

I’ll keep you posted as I proceed with the Varpa-Mac faceoff. Of course, if you have an opinion on these looms, I’m happy to hear that!

With my next show looming, I’ve been working hard to get new things woven and old(er) things fringed, wet finished, pressed, and labeled.

For instance, while watching TV this weekend, I strung ribbon and hung my tags on those 71 bags I’d made a few weeks ago.

I finally trimmed the fringe and photographed the rainbow shawls I’d woven in July. In hindsight, I wished I’d reversed the two colors I’ve pointed to in the picture, but they’re ok – not so bad I’m embarrassed or anything.

I figured out which one I’ll hang on to and send to the professional photographer for my images for next year’s shows.

Then in response to an email from a customer, I realized I’d never photographed some of the rayon scarves I’d already finished, tagged, and packed. They are both a baby blue rayon, woven in huck. I probably don’t use the correct terms, but the first is what I think of as traditional huck…

…and the second what I call huck ‘windows.’

I’m hanging on to one of these for the professional photos…I think the openness will photograph well.

I got the fringe twisted on those silk scarves I’d recently woven on the Varpa, then got them wet finished. I was struck by how dramatically different the two sides of the scarves are. The sheen of the silk is much more apparent on the lighter side, the pattern on the darker side.

The burgundy one, which I wove first, may be my favorite,

although I really like the coffee one, too.

The blue is my least fav.

I’m trying to decide if I’ll hang on to one of those for the professional photos. I think I’ll just put them out and see if they sell.

I also finally got the fringe trimming & pressing done on the yellow rayon scarves I wove on the Varpa. Although they’re only a 4H pattern & I planned to weave them on my counterbalance, I decided I’d give the Varpa a trial run.

I’m wet finishing more scarves today, and hope to get a few cotton shawls measured & on the loom. Gotta run!

After warping up the Varpa and getting everything all tied up correctly, I decided I’d change the treadling for each of the three handwoven silk scarves, as well as the weft color.

For the burgundy scarf I used ‘tromp as writ’ — meaning I danced across the treadles in exact same pattern as I’d threaded the harnesses.

For the next one I decided to treadle basically a straight and point twill, eliminating the advancing twill sections.

Here’s what it looked on the loom like with a Pacific Blue weft.

That one was a bit harsh for me, I think because of the combination of the sharp angles in the weaving pattern and the dramatic difference in the warp and weft colors. So for the third I softened everything up. I treadled only the advancing twill with just a small point between each pattern.

Then I used a light coffee weft, which also softened the look. Again, here it is on the loom.

These scarves were not quick to weave. I had to get used to treadling the Varpa, and had to pay attention to 360 threads to make sure I wasn’t making weaving errors. After that, I really needed to get a quick, easy warp onto the counterbalance loom so I could feel reasonably productive in preparation for the upcoming show. So I decided on bookmarks. I threaded in a rosepath pattern, treadled in a variety of patterns, and got 32 booksmarks woven.

That made me feel good.

So now I’ve wound a warp of 170 ends of natural 8/2 tencel and have beamed it on the counterbalance. (By the way, I’m a complete warping valet convert.) I’m going to thread in a modified Ms & Ws pattern treadle in a variety of ways, and use a different weft color for each of the four scarves. Gotta keep moving!

|

|