|

|

Warning to non-weavers: this is a very weaverly post. While you may not understand all the language, I think you’ll still find the photos interesting.

After successfully completing a warp of 4 4harness scarves on my new Varpa, I decided that it was time to give it a run with 8H. I knew I wanted to try my next variation of the snowflake twill. My initial intent was to make silk shawls, as I had before. However, the 20/2 silk that I have now is about 50% finer than the silk I used in April, so I needed to have 50% more threads per inch to achieve a stable cloth. That meant 36 threads per inch, and for a shawl, 700 threads total. Given the fact that I need to produce more finished pieces for the next show in a few weeks, I didn’t want to take the time to wind and thread all those ends, so I went for the same pattern but in scarf width.

That decision made, I did the tie up, beamed the warp & threaded the loom, & set off.

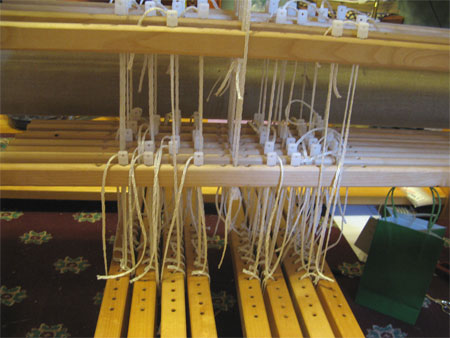

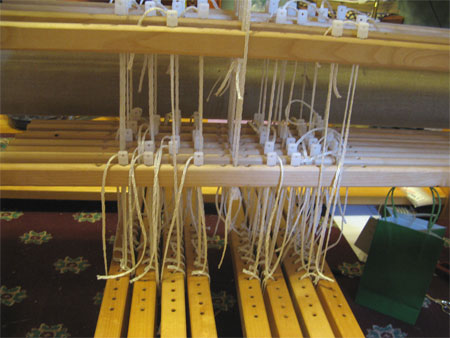

Here are a few pictures of the Varpa all tied up. You can see why it’s said that countermarch looms are just sticks & strings.

Here’s a close up of the lamms & teadles tied up. 16 lamms, each tied to each harness. 8 treadles, each tied to each harness = 64 tie ups. Make each string as close to completely even as possible. With Texsolv, you can’t get them perfect, as the holes are approximately 1 cm apart, so sometimes they’re either a bit high or a bit low.

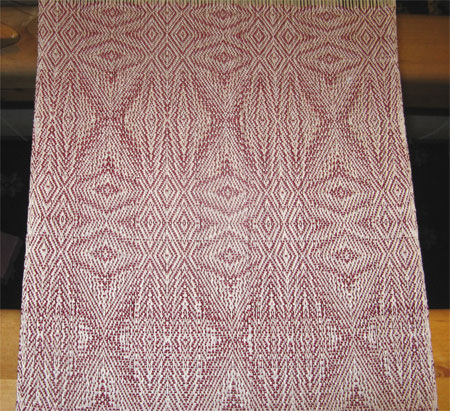

So I started weaving. I was pleased with the way the piece looked.

But my goodness, the weaving was incredibly slow! That was because the treadles were so close together that I had to really play with the side of my foot to press down just one treadle at a time. Not fun. If you look again at that last photo, you’ll see that those treadles ‘float’ together — by the front of the loom, where my feet are, they touch each other.

I went to Weavolution and asked for other people’s ideas of how to correct this. I already had spacers on the backs of my treadles, which is what people suggested, so I needed to come up with something else.

I thought about it, and decided I’d change the tie up. My Varpa loom is able to accommodate 12 harnesses, even though it only came (to me, at least) with 8. So there are 4 more holes in each of lamms than I need. I figured if I spaced out how the treadles were tied to the lamms, it’d leave some room in between treadles by my feet.

So I climbed inside the loom, and tied my treadles to the lamms using holes 1, 2, 4, 5, 8, 9, 11, & 12. That left holes 3, 6, 7 & 10 empty. Now my treadles were rather in pairs, and I could easily find the one I wanted with my feet. Here’s how the treadles looked after this new tie up system.

So I sat down to weave much more happily.

Hah!

It didn’t take too many picks for me to realize that I had a mistake in my tie up. Actually, I’d tied it up exactly like I’d planned, exactly like my Fiberworks program had shown. But with one switch on treadle 8, I could dramatically improve the design.

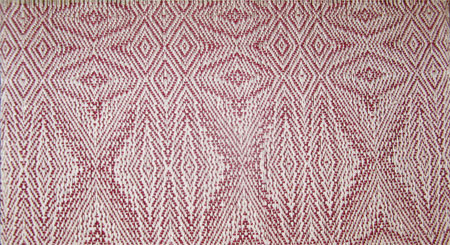

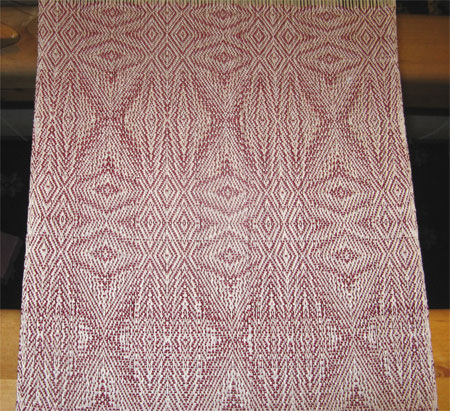

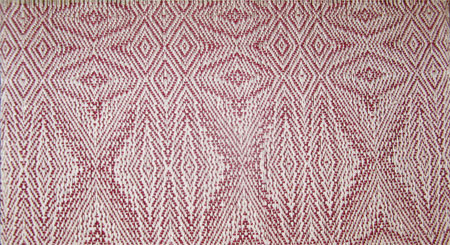

Here’s a shot with the cloth before & after the change.

It might be easier for you to see the difference if I show you the bottom of the cloth, where the burgundy color is more pronounced than the top.

Do you see it? Those horizontal lines? Just to make sure you do, here’s a close up of before…

…and after the change.

With all now in place, I easily finished weaving this scarf. Enough warp on the loom for two more, each of which will be a different weft color. Then I’m going back to my beloved counterbalance for a bit, since I can get things done much more quickly at this point, & I need to to produce more in the next two weeks!

You know me too well. You knew that I’d find a reason for continuing to work on the Varpa, didn’t you?

Well, my heddles aren’t here yet, scheduled to arrive tomorrow, but I thought about it, and decided it made most sense to try a 4 harness pattern that I’ve woven before — on my counterbalance loom — on the Varpa. There are several differences in the tie up on a countermarch loom (the Varpa) from either a counterbalance or a jack loom (the Macomber). I figured I shouldn’t make it more complex than it needed to be for my first attempt – go with a 4 harness pattern.

So with some false starts and a few missteps, I started by doing the tie up. It made sense to me, and when I tested it out, the correct harnessses lifted and lowered. GREAT!

On to beaming the warp and threading the heddles.

All went well. In fact, I found the threading easy; with the knee beam, breast beam, and beater out of the way, I could get very close to the harnesses. I tied on to the front beam, and was off weaving!

It’s a Swedish lace, which I think makes perfect sense for the maiden voyage of this Swedish-style loom. Ok, Varpapuus were actually made in Finland, but it’s close enough for me. (How American-centric is that?!)

I’ve got half of the first scarf in this warp of four woven already. Not as quick as on my beloved counterbalance yet, but I’ve only been working on it for a short time. I’m confident my speed will improve with practice on this loom. (The color is very off in this photo.)

Because I’m so short – specifically, because my arms are so short – I’ve already made a modification to the loom. It’s just temporary at this point, until I figure out the right combination, but it’s already made the loom fit me better. I’ve clamped and/or tied blocks of wood onto the castle so the beater doesn’t go as far back as it did. It makes it much easier for me to reach it.

Don’t ask me why I’m comfortable making modifications to this loom but not to my Mac or even the counterbalance. The counterbalance is pretty perfect just the way it is; the Mac never felt like home. I hope, and at this point believe, that the Varpa has found its home, after having only short stays with its last two weavers.

I drove 5 hours in my rental van and bought a loom, packed it up, and drove 5 hours home. It’s an 8H Varpapuu, made in Finland. The loom can accommodate up to 12 harnesses, and I am thinking I’ll add them in the coming months. But first I have to get the loom all set up, learn how to tie up a countermarch loom, and get comfortable with weaving on it with its 8 harnesses.

Wait. Back up. When I got to the seller’s house, she was very eager to show me various features and components of the loom, and how to set it up and tear it down. I took several pics to help me remember what things looked like. It’s a countermarch loom, so it is both similar to and different from the two floor looms I already own – a counterbalance and a jack.

Here it is from the front.

And the back.

The Varpa has a brake that looks tough!

Laurie, the woman I bought the loom from, told me it was quite difficult to set it up alone. Hah! Clearly she doesn’t know me. This only made me want to do it more.

So I came home, emptied the van, and set up the frame. By myself, of course.

It wasn’t the easiest thing I’ve ever done, but it sure wasn’t the hardest, either. Once I had that done, I said to myself, “You’ve got a show in a few weeks. Leave the new toy alone and go weave!”

“Okay.” I replied, pouting.

And I did. For a while. Then I was back in the dining room. Put a bit more together. Made myself go back and weave. Took another break and did more assembly. And exchanged another email with Dawn McCarthy, a veteran weaver who’s been REMARKABLY patient and generous with her time.

And so it went till I got to here.

Now I really am at a standstill. I had to order Texsolv heddles for harnesses 5-8. They’re scheduled to arrive on Tuesday. Then I’ll want to try out an 8H pattern with my new baby. I doubt I’ll be able to restrain myself till after the show.

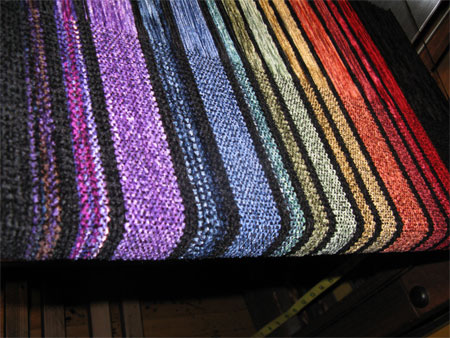

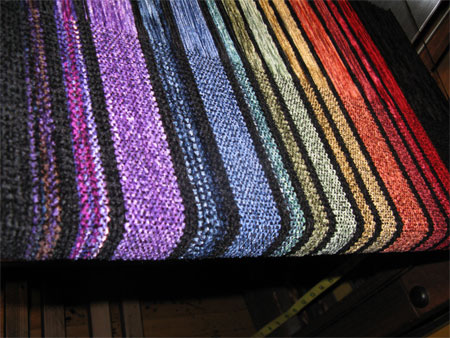

In the meantime, I have been weaving. I think the layout of this batch of Rainbow rayon chenille shawls is better than my last one. At least I thought so till I went back & looked at that photo.

I guess I just love the rainbow shawls. Not fun at all to beam a 9 yard, wide warp of rayon chenille, but for me, it’s all worth it. Making these handwoven shawls just makes me smile.

That room may not look impressive to you, but it does to me. Yes, there are still things in boxes around the edges, but that’s only because I don’t have any place to store them. Yet.

This is the room that I made jewelry in for more than a decade. I haven’t yet given it up totally, and still have thousands of beads and lots of other supplies. But today I transitioned what was first a dining room and second a jewelry studio in preparation for its third incarnation – a secondary weaving room. I’ve made all the necessary arrangements (agreed upon price with the seller, reserved a rental van, secured a place for my dog to go for the day) and will be picking up a new-to-me Varpapuu loom on Thursday.

So I had to totally clean off the table that had served as design and work area for jewelry and remove it. In the process I had to take pictures of some completed scarves so I could put them away (don’t get excited – several have to be re-shot), figure out what of the stuff on and under that table could and should be tossed out, and organize my first batch of beads and supplies for sale on CraigsList. I only listed stuff I haven’t used and haven’t wanted for years. For the last many years I worked pretty exclusively with semi-precious gemstones, and I listed only glass. And not high quality glass at that. We’ll see how it goes before I start doing more organizing and photographing of more of the jewelry supplies. But I will need to do that to clean off shelf space for more weaving supplies.

Away from that tediousness to the exciting part – that new Varpa loom! I currently do 90% of my weaving on my little counterbalance, the other 10% on my 8H Macomber. But as I’ve said before, that Macomber isn’t my cup of tea. It just never seemed right to me, never made me happy to weave on it. For some time I’ve thought I’d like a countermarche loom, since they are more similar in operation to my counterbalance than a jack loom like the Mac. So I’ve kept my eye on CraigsList and other sites for a loom I wanted at a price I was willing to pay. It took several months for this one to come up.

My plan is to get the Varpa set up, get comfortable with it, love it, and then sell the Mac. Not only will that get me back some space in my house (I had to move that dining room table out to my porch temporarily), but it will help pay for the Varpa.

Keep your fingers crossed for me that this is how it will work out.

It’s been a very busy spring & summer at my house. Men have been here doing work of one type or another pretty consistently.

After living with a not-so-prolific spring as my water source for 23 years, I decided to have a well dug. This meant big, heavy equipment making lots of noise in my yard for a few days.

Sometimes in the rain, which didn’t stop the drilling.

Given how dry this summer has been, I don’t think I got this job done a minute too soon.

To pay for part of the well, I worked with my friendly forest management guy, and we decided that this was the year to harvest my dozens of large ash trees. The emerald ash borer stopped the movement of firewood a few years ago, and it’s possible that you won’t be able to transport logs by next spring, so the time to get these trees is now. Hauling lots of logs out of the woods isn’t easy for either the machine or the operator. When the skidder has seen as many miles as this one, repairs are common. And when the sun’s blazing, working in the shade is a definite improvement, even if it’s just a large umbrella hooked to saw horses making the shade.

Meanwhile I found someone to do a job that’s been waiting for over 20 years — insulating and finishing the outside walls of the exposed parts of my basement. Not being too hung up on cosmetic issues, my primary motivation is keeping my basement cool in the summer and warm in the winter, instead of its current reverse operation. I’m sure this job WILL look great when it’s done, just to be icing on the cake.

Then yesterday I got to spend the day with a little man who was very busy indeed.

Walking is very tricky, but these woodpeckers make it really easy. He can almost run!

Making motor noises with your mouth clearly helps things move along better.

I have no idea how someone this small learned how to turn the birds when he came to the end of the road, but he did it well. Pull back, turn the front end, repeat until the path ahead is clear.

As if all that outdoor deck walking wasn’t enough, when we went back inside he had to climb Mt. Woodrow to reach Mom. Twice. Butt bumping down the stairs with Dad was a lot of fun, too.

And me? What have I been doing while all those males are working? In addition to weaving daily (more weaving than I’ve photographed & posted), last night when the little guy was in bed & Mom & Dad enjoyed a night out, I cut pillowcases for 71 bags. I got 30 sewn last night, came home this morning and sewed the remaining 41. Threw them in the washer, and hung them on the line.

After they’re dry I still have to thread each with grosgrain ribbon and my Second Wind Weaving tag before they’re ready for the next show. Although it’s a bunch of work to make them, most of my customers comment on them giving me pretty constant positive reinforcement to keep doing it.

I do find it interesting that a fair amount of people want to look at all the bags and pick out ‘the perfect one’ for their scarf.

Your turn: So what’s been happening at your end?

|

|