I’m doing a bit of playing catch up here. I’ve been weaving as fast as I can, and now that I don’t need to try out a new loom, make decisions about which loom is staying, or do the work to sell the Varpa, I can get much more accomplished.

The first thing I did was warp for 2 rayon scarves on the Mac, to be sure that the hints the weavers on Weavolution had given me would work well. To start, I sanded the breast beam with increasingly fine grades of sandpaper, starting with 80 grit and working my way to 600. Then I finished it with Danish Oil. An interesting product – that. Before I bought it I assumed it was, as the name implies, an oil. Not so. It’s a product that has some plastic polymers in it, so dries hard – no residue to rub off on fabric.

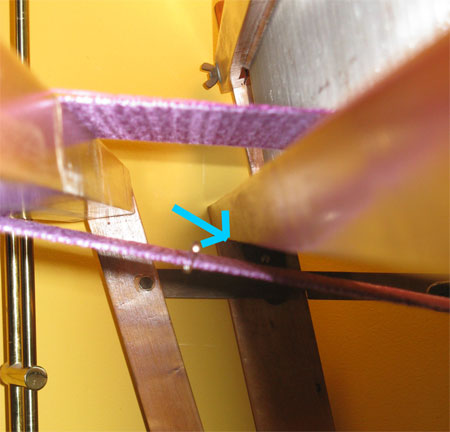

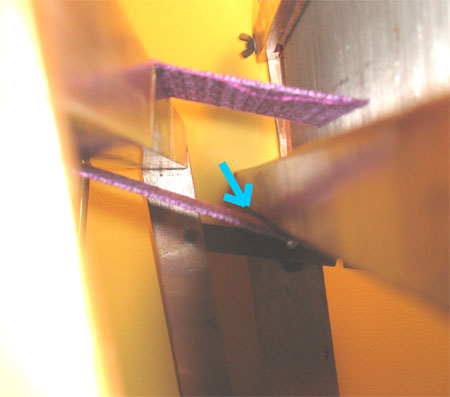

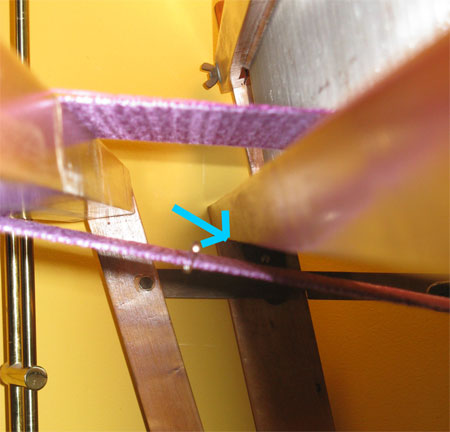

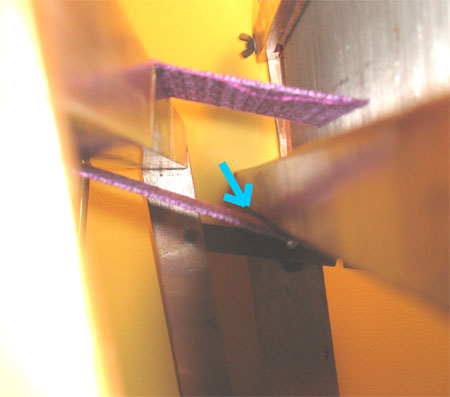

Anyway, as I continued to read the hints I was given, I realized that one weaver had hit the nail on the head with my problem. I was advancing the cloth beam too far, so the bottom of the beater was hitting on the finished fabric and pulling that weft apart. Here are a few pictures so you can see what I mean.

In the first one the cloth beam is advanced correctly. You can see the space between the bottom of the beater bar and the woven fabric.

In the second (sorry for the quality), I advanced the warp too far, and the bottom of the beater bar hits that woven cloth. With a fine and/or loosely sett warp, this will be deadly.

Now that I know exactly what causes that problem on the Macomber loom, I can avoid it. I’ll probably try to come up with some type of ‘stop’ so that I can’t advance it too far. IMHO, while there are many great design features on the Mac, this is a design error. It was impossible to do this on the Varpa, and is also impossible to do on my counterbalance. I know there are very good reasons not to advance your warp too far at once, but this shouldn’t be one of them.

My test warp for this new attention/technique on the Mac was a lavender rayon threaded in an 8 harness Ms & Ws pattern. I used a red-violet weft in this first scarf.

The second weft was a navy rayon. I can’t show it to you because it’s one of the nine pieces I dropped off at a professional photographer’s today so he can shoot them for my show applications for next year. I wanted to get the weaving to him so he can take his great pictures & I can get them back to sell at my fall shows. I forgot to take a photo of this one before I took it to Tim Fuss.

Then, because I knew I could go faster, I went back to my trusty counterbalance loom for everything else you’ll see here.

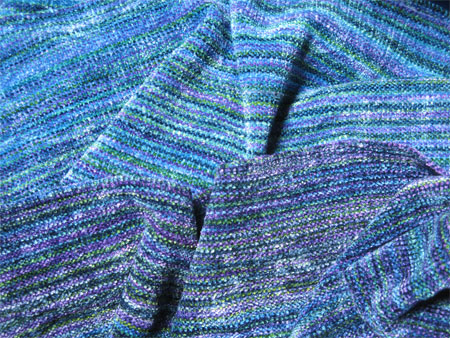

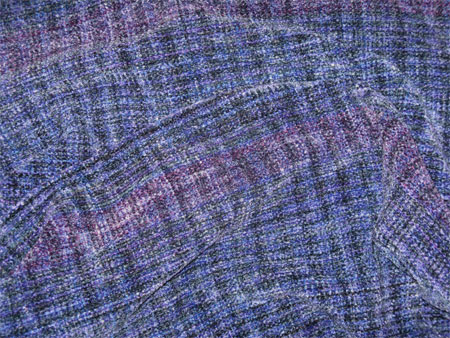

First some of Tammy’s hand painted rayon chenille in Blue Violets. I put a stripe of some of her purple yarn in just for a bit of contrast.

Because rayon chenille is a slow fiber to beam, I moved to a lovely lilac silk-cotton blend, making some huck lace blocks. The second picture, the close up, is much more accurate in color.

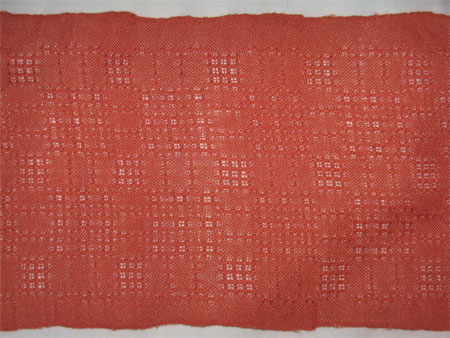

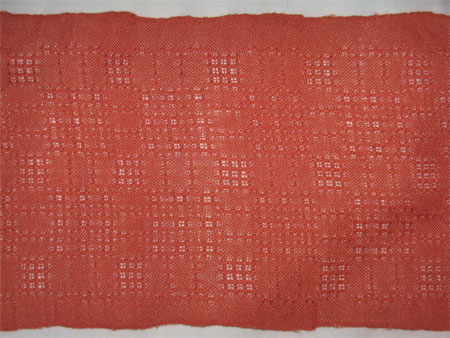

Then, because I was on a lace blocks roll, I decided to weave with some of the lovely orange cashmere-silk I’ve used before. I’ve been out of this color of scarves for months, and although I haven’t sold many cashmere-silk scarves this year, I thought people might like the orange.

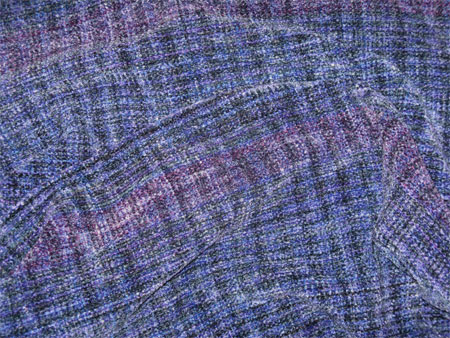

Hmmmmm. Problemmatic. I like the lace pattern,

…but the yarn was much more challenging than it should have been. Especially along the selvedges. Absolutely none of the techniques I tried made smooth selvedges. They looked bad on the loom, they looked bad after wet finishing.

I’m sure I’ll be more critical than most of my customers, but needless to say I am really disappointed in these scarves. I had planned to take them to Tim for photos; obviously I didn’t do that. Sure don’t want a jury to think this is typical of my work!

I’ve woven a few other pieces I still need to finish, and I’m getting more on the loom tomorrow morning. Some more of Tammy’s hand painted lovelies. In 12 days I’ll be loading the van for the next show, and I still have to weave more bookmarks, warp the rigid heddle, and finish the magnets & cards I started last winter — specifically for this upcoming show. I have other ideas for things I think will sell, but there’s not enough time to make more new products. Better to have more ideas than time than the reverse.

The hillsides here are starting to be works of art. I love the beauty of autumn in western New York!