…if you consider a dope slap to your own head as a hit, that is. The mistakes, aka poor choices/unwise decisions, haven’t stopped yet. Let’s stick with the weaving for those cards for now.

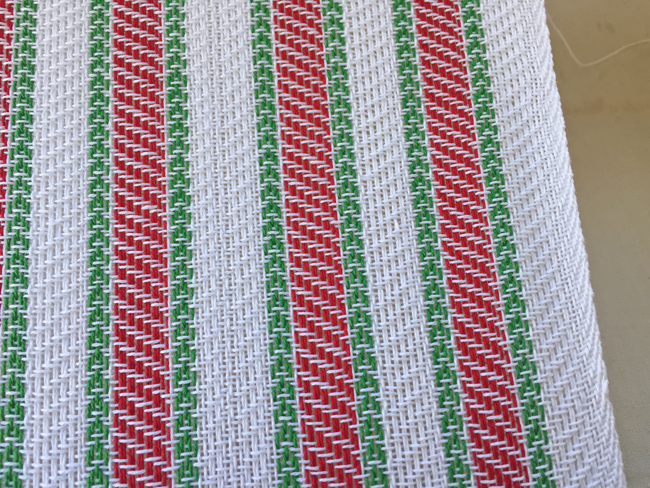

I wanted to get 3 cards across the width of the warp. At 3″ each I could just make it, if I sewed my stabilizing stitches on the machine carefully, just far enough apart for me to carefully cut between those lines. I appropriately switched to a light cream colored thread for this task so that I would be able to see the lines for my cutting.

Sewed the four rows of stitching. Also sewed some stitching width-wise so I could cut off a length and make sure everything fit.

WHAT?!?!?! Not even close!! HUH?!

Are you ready for dope slap #2?

Sure, I knew that the card blanks I ordered had 3″x3″ windows. But I just hadn’t planned for the fact that what you’re going to put into those windows needs to be larger than 3″x3″. A 4″ square will do it. So even with all my work to add extra ends to each selvedge, there was no way I could get 3 cards across. (You may be thinking that I didn’t number that dope slap correctly, that it should have been #1. You’d be wrong. Dope slap #1 was sewing those lines on a yard or more of fabric. Should have only done a small amount for my sample.)

So I played around and realized that I could reasonably get two cards across the width. But only because I had taken all that time and energy to add threads to each selvedge. It would have been too tight otherwise. (Refer to Mistake #7 in the last post) Whew!

Thankfully, one of my earlier errors (Mistake #5) that caused me to put on lots of extra warp also came in handy here. If I hadn’t done that I wouldn’t have had enough woven to make my cards.

After figuring out how to get two cards across the width I went back to my sewing machine and sewed four more lines of carefully close stitching and cut them apart. I also sewed lots of rows of stitching width-wise and cut them apart there. I decided that in real life I was the only one who would notice, or care, about the earlier rows of stitching that now show through my window.

Today I assembled 30 cards. I’m not sure how many I really need, but I think that will do it. I have extra fabric and extra card blanks if needed. And the good news is that I am pretty sure I will retain lots of those lessons and not make those mistakes again when it’s time to plan next year’s cards. 🙂

****************************

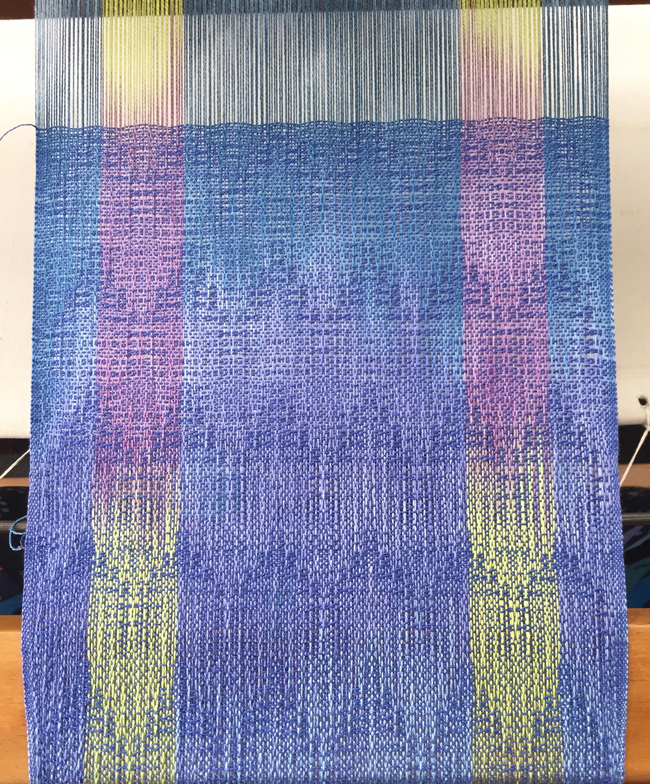

While all that was going on, I decided to warp for more towels. I’m working on stash reduction, so decided to forgo lots of color for some great neutrals. Here’s half of my warp measured out on the warping mill.

While I have some favorite drafts for sure, I also like to try new things. Or at least new to me. Weaving has been around for centuries and many (most?) drafts have been around for a long time. I’d never woven Ms & Os and decided that it would work great with my neutrals, adding a bit of texture.

Beamed, threaded, sleyed, lashed on, wove a header, and found a threading error. Undid part of the lashing on and fixed that error, re-lashed, evened out the tension, wove another header, found another threading error. Did that yet a third time. I wouldn’t ever give myself a dope slap for a threading error; those things happen. But when I found that first error, why didn’t I look more carefully and find the second? And then when I found the second why didn’t I find the third before I proceeded and had to undo again? DOPE SLAP!

Ms & Os is a very simple treadling, and I was flying along on that first towel.

While under tension on the loom, weaving almost always appears flat, even weaving that will have texture later. The warp tension is the reason for much of that, but also the threads don’t have a chance to shift widthwise until the piece is off and in water. So while I was liking it, I wasn’t loving it.

Weaving proceeded. Eventually there was enough length woven that I could see the underside of the cloth. Uh oh! Where are these long floats coming from?

I went back to my computer and checked the back of the design in my software. Nope, that shouldn’t happen. Double check the tie up – oops, I’d made an error. Again, not the first time, and likely not the last time, but not worth a dope slap.

I stopped weaving for a bit and thought. Would I unweave 2/3 of a towel? No, I would not. Would I simply call that a loss and start where I was to weave the towel? I could, but I was pretty sure I wouldn’t have enough length to get 8 towels out of the warp them. So I decided to keep weaving that towel, figuring I could turn it into a bag or something that had a definite wrong side so the floats wouldn’t matter.

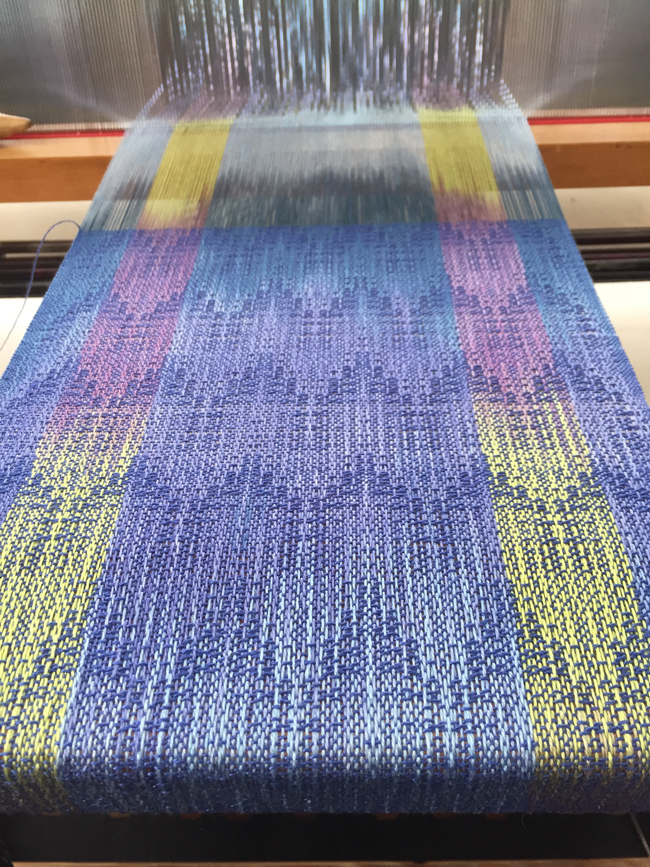

I wove the remaining 7 towels on the warp, cut everything off, and looked at what I had. You know what? I really liked these towels, even before I’d wet finished the to develop the intended texture. I didn’t want to lose that first one, and I knew that the 8-end floats I had were far too long to be useable as a towel.

No problem. This is a very simple structure and needle weaving will be easy. If you’re one of my regular readers you’ve heard me talk about how I hate to needle weave. But this time I decided it wouldn’t be hard and I could do it. So I set to work.

It wasn’t hard, but time was being eaten up at an amazing rate. And while I could listen to an audio book, I couldn’t watch anything on TV as I needed to pay attention constantly.

I timed myself for a bit. It took me an average of 10 minutes to correct one warp thread for the roughly 21″ needed. That’s not bad, right? Yeah, not until you realize that I had 62 threads to fix. 62 threads x 10 minutes = 620 minutes = more than 10 hours!!! How long would it have taken me to cut out that warp when I first saw the mistake on the loom and start again? Maybe an hour. Dope slap!!

So now all the towels are off the loom, the needle weaving done, the towels washed, dried, and pressed, ready for hemming. Hmmmmm….

I’ve already said I knew I’d get some texture with this weave structure. I could have, and should have, realized that meant that I shouldn’t do a plain weave hem. Plain weave spreads warp threads out to their maximum allowable width. So of course, after wet finishing and the draw-in that would create the desired texture, the hem fans out.

Since I hand hem my towels, I MAY be able to ease the hem in with my hemming. Or I may not. I SHOULD have woven the hem in the same Ms & Os pattern. Even if I had used a much thinner weft for the hem, I think plain weave would still have given me a flair. I’m not giving myself a dope slap for this error, but it is worth a big sigh.