Following a pattern established by Meg over at Unraveling, even though she’s apparently not playing the game this year, I took shots of my looms as they stood on New Year’s Day, 2017. In no particular order….

This is a shot of the treadles of my Macomber. I like this angle, even the fact that you can see some lint in the slot of the treadles. There’s no warp on this loom at the moment, although I have three orders that will be woven on it over the next few weeks.

Next is my rigid heddle loom. This little loom is currently both happy and sad. All that lint in the heddle is a reminder that it had a project on it not that long ago…it wove a lovely alpaca houndstooth scarf that sold very quickly in my Etsy store. You can also see the ends of some wood sticking out underneath it. I bought the pieces needed to add a second heddle to the loom, which will make it even more versatile than it already is. It’s happy about those two things, even though it spends most of its life on a top shelf in the weaving studio.

My sweet little counterbalance loom is currently acting as a catch-all. 🙁 A towel, bobbins, a book, yarn, samples, all just resting on her. A warp is not currently in the planning for her, either.

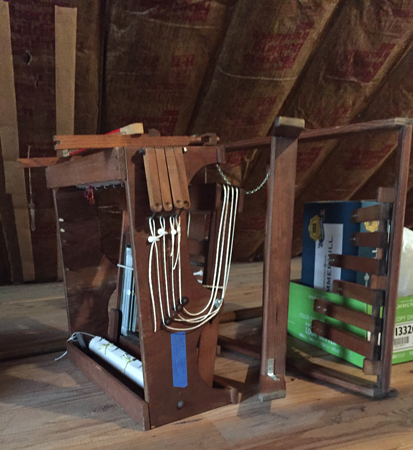

Even sadder is the Missouri, stored in the attic. It did make it down for the supplemental warp workshop, but spends 98% of its time alone in the dark and either freezing or roasting under the eaves.

So why oh why is there a newcomer? Who the heck is this and why is it here?

Well, at the supplemental warp workshop I got a chance to weave on someone else’s Dorset loom. I really liked it. It’s a 4 shaft, direct tie up, folds for transport, well made, decent length from front-to-back beam makes for a decent shed. Well respected little loom, made by FC Wood in Waterford, NY. Hasn’t been made in decades. Not a ton of them around. Several other loom manufacturers have copied the design either directly or some with modifications. I decided I wanted to see if I could find a Dorset loom to buy, and if I could, I’d sell both the counterbalance and the Missouri.

I was lucky enough to find one within the Rochester Weaver’s Guild! I snapped it up, and have put a towel warp on it to make sure I like weaving on it before I sell the other two looms. Actually the above photo was taken a few days ago, when I was threading the loom. It’s not the most comfortable loom to thread, so I put it up on bed risers to make it a little easier. That made me cautious and hesitant about my purchase. But once I had it set up, wow. Weaving is a dream. And this spoken by someone who’s never had a direct tie up loom before and didn’t like working on one.

For you non-weavers, direct tie up means that there are only 4 treadles, one for each shaft, and each treadle can only be tied to one shaft. So when you’re weaving, you most often need to use two feet at the same time. Just to weave plain weave you’re lifting 2 shafts at once. I wasn’t sure I’d really like it, but I do. It is remarkably easy to treadle, and since there is no changing of the tie up, there’s one less step to set up for each pattern. I can change the weave pattern mid-stream if the spirit moves me. On my other floor looms changing the weave pattern often necessitates crawling under the loom and changing how the treadles are tied to the shafts.

So yes, I will be posting my counterbalance and Missouri looms for sale. They’ll both be very affordable, and I’m hoping that a relatively new weaver will jump on them. That would make me really happy. Especially for the counterbalance. She’s been a sweet loom and deserves continued attention and use. Know anyone who might be interested?

I bought my Dorset back in the 70″s. 24″ width, with a modification to the tie-up. It’s called a “Ross tie-up” after Marjorie Ruth Ross, a master weaver in Ithaca. This tie-up has the treadles running 4 – 2 – 3 – 1. Dance your way through twill and overshot simply by angling your foot across the odds then the evens. Don’t know if a standard Dorset tie-up can be modified from 4 – 3 – 2 – 1.

Marjorie’s looms are now at the Thousand Islands Arts Center in Clayton, NY. They have a stellar textile library.

Thanks, Dreamer. Actually, my plans/mind changed, and I ended up selling the Dorset. I decided that since I weave to sell, even with its benefits, a direct tie up loom was not efficient for me. I still have both my counterbalance and my Missouri looms. 🙂

Very cool-looking loom, sounds like you should be happy with it! Your bed-risers gave me an “aha!” moment. I have a folding Lillstina loom I am nearly finished refurbishing, and I’m anxious to weave on it. Sat down to test the treadling and found I am too tall (or too long-legged) for the loom! Bed risers might be the answer. Have you actually woven on your Dorset with it up on the risers? You say you set it up that way for the warping/threading process, but will it still be stable when you beat? If so, I may be able to use my Lillstina yet!

Sorry, Rebecca, I used the risers only to thread the loom. It would definitely NOT be stable enough to weave on the risers. And actually, I’ve decided I jumped too quickly. I am going to sell the Dorset and keep my sweet little counterbalance – a better fit for me as a semi-production weaver with 6 treadles, plus a little wider.

Good luck with your Lillstina!

Thank you for carrying on the tradition, Peg. I’ve been away from weaving for a while but hope to get back in due curse this year. Happy weaving, and good times with Jack.

Happy to do so, Meg. You were the lead for many years!

How wonderful! I’ve heard nothing but good things about those Dorset looms. I’m thinking there are also some that are 4/6? Enjoy and here’s to quick sales. 🙂

I don’t know if there are 4/6 Dorsets, Theresa, but I got used to direct tie up immediately!