…Baby wraps, that is.

I mentioned that my insert eye heddles arrived. In a big bundle of 200.

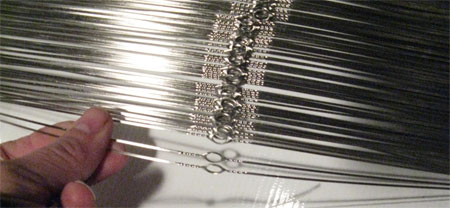

For non-weavers, each thread in a warp goes through the eye of a heddle. That heddle is on a harness, which is what gets raised or lowered to make a weaving pattern. Here’s a closeup of those insert eye heddles.

To prepare for weaving the baby wraps, first I had to remove a cotton warp that was on the loom. I had warped it back in early August for something I had in my mind. I wove one of the planned three pieces and realized that my idea was not going to work. The doubleweave itself was fine, but the finished product had only the most vague comparison to my ideal. I thought and thought, tried a variety of modifications to it, and decided it was simply a no go. I thought about what else I might be able to make from the warp that I’d taken the time to measure and thread – almost 800 ends – but I couldn’t find a use. So just take it off and toss the cotton away. Sigh.

Next I had to count the heddles on each of my 8 harnesses on my Macomber loom, compare the numbers I had on each harness to the number I needed on each, move heddles from over-loaded harnesses to harnesses that needed them, and then add more from the batch of new heddles. I spent about an hour and a half doing that. I still need to divide the number on each harness in half, since my harnesses have a center support. Fortunately the heddles can be moved during the threading process if needed.

Now to actually measuring out the first warp, which will make two wraps. A friend from my local guild, the Southern Tier Fiber Arts Guild, gave me an old, handmade warping mill that was in her attic, unused for years. Actually, she’d lent it to me a few years ago to try out. I returned it to her, and it returned to her attic. She was glad to move it out to someone who had a need. Thanks, Carlyn!

The mill’s not perfect, but it should make the measuring process go much quicker than it would on my warping board. With the mill, you start by measuring out a string that’s the length of your desired warp and wrap it around as a guide string. You can see mine on here. Then you follow that guide string with your warp, making as many bouts (groups of threads) as are reasonable and appropriate. With 940 ends, I’m thinking I’ll have 4-5 bouts in this warp. That would make each bout 188-235 threads, which may be too much; I may have to make 6 bouts of 156 threads. Time will tell.

So what would make the mill better? I’d like it to be an even 2 yards around (it’s an unusual 2.75 yards), to be 4′ high (it’s just 2′ high), and to have a brake on it (that helps when you’re taking the warp off the mill to carry it to the loom). It should have some adjustable pieces to make the ‘cross’ (see those 3 dowels? That is where you make the cross.) and allow you to end your warp wherever suits your length. On the plus side, I like the floor stand and the fact that the top part easily folds down flat to take up little space when it’s not in use. So I’m trying to get someone to make me a new ‘top’ for this mill. I don’t have any takers just yet, but I’ve only started looking.

Anyway, I’m planning to measure the first warp today. That’s likely as far as I’ll get, since I won’t be home on Saturday or Sunday, but I can’t wait to see how lovely the colors will look. I think Meghan will like to see the colors she picked, too!

Leave a Reply