Yesterday I took Jack out for his regular afternoon walk. It’s been very cold, so he usually chooses to walk only as long as absolutely necessary to accomplish his mission. The afternoon walk was once around the block, which was what this walk often is any time of the year. Fine.

We got back home and I sat down to do some computer work. Jack was sitting near me in the room, just like always. He was, I thought, chewing on his bone. Swell.

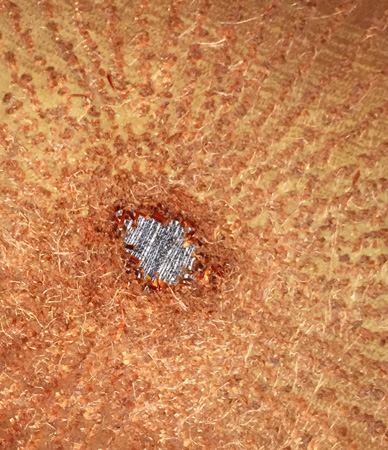

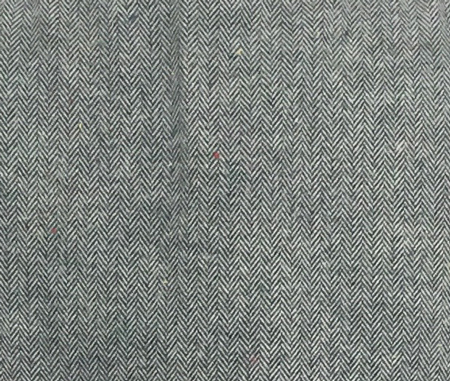

When I was done on the computer, about an hour, I stood up and saw this.

WHAT THE HECK?!?! Jack hadn’t been chewing on his bone, but pulling things out of the rug!

In 2 years he has pulled out a total of maybe 2 dozen, and I always thought they were done in error when he was grabbing for a toy. But this?!?! This is BAD!

To make it as bad as possible, this spot is dead center in the middle of the rug. It’s not like I can put a chair over it or something. I have no clue if I can put those parts back into the rug; I will try, but I’m betting it will either be near impossible or will look like hell when I’m done, and that I’ll be looking for a new rug. I’ve thought about weaving one, but wasn’t really ready to do that. Especially since this rug is a 5′ x 8′. Quite a large rug for handwoven indeed. Your suggestions will be appreciated.

In another what-the-heck is a new problem with my Adobe Photoshop Elements Editor. I have used this program for years, ever since I’ve had a blog, for sure. It’s how I edit my photos and size them for the web. When I got my new laptop, I’m thinking about 18 months ago, I had to change the version of the software and get used to it, but it works very similarly, so fine.

Except starting a few days ago, not fine. I open an image. Crop and adjust as needed. Go to Save for Web and resize. Hit Save. I consistently get an error message: “Could not complete this operation. The specified volume could not be found.” It matters not what file location I choose.

I’ve figured out a work around, but come on – what the heck happened?!?! My work around is more steps: Go to Image Resize. In a few clicks I’ve gotten it to the size I want. Then go to Save as and rename the file so I now it’s the modified one. Then click Save, and it easily goes to exactly the same location as it couldn’t find a minute ago. Again – what the heck? I can’t find anything in Preferences that would seem to have any impact. Again, your suggestions will be welcomed.

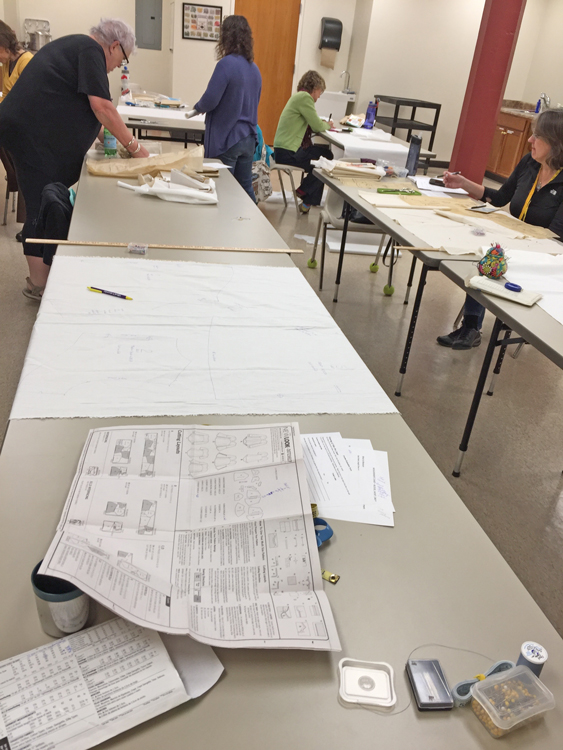

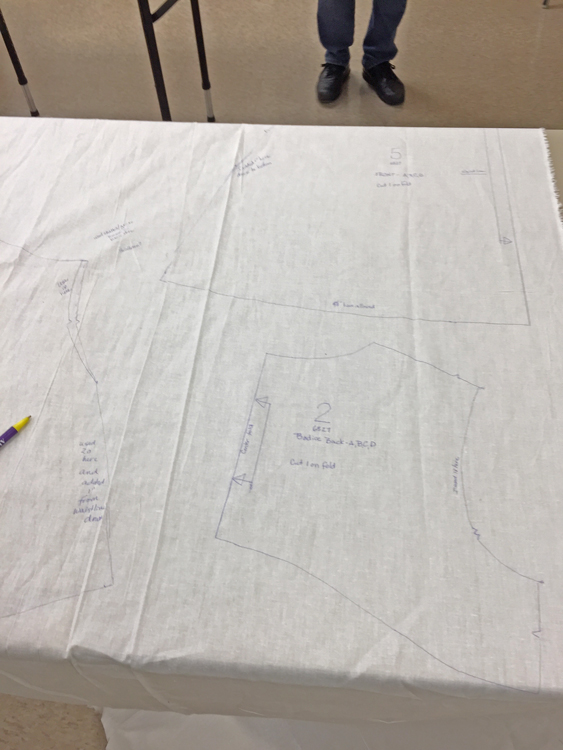

Ok, so here we are on December 31. A few days ago I had a minor freak out when I realized that I had only 4 days left in the month and had completed NOT A SINGLE THING for my inventory. YIKES!

So I put the black and white 8/2 tencel scarf warp on my counterbalance loom. I figured I could weave it off relatively quickly. And I did. I’m not in love with the huck weave structure I chose, but it’s okay.

This was an experiment, to see what I might like best for weft for the shawl warp I’d painted at the same time. First I did a gradient weft: 16.5″ of a solid color, my standard 64-thread gradient to the next solid color, repeat. I had 4 solids I used: black, dark gray, silver gray, and white. It’s okay, but not my favorite. I do like those spots of black on one end of the fringe – reminds me of porcupine quills.

Next I used solid white for the weft. I like this one better. You can see that one of the fringes in the middle of the white end sort of came undone in the wet finishing. No idea why, but I’ll have to fix that.

I had enough warp left for one more scarf. What color would I choose? As I thought about it, I had a light bulb moment. My cowls have been selling pretty well, so instead of making one more long, fringed scarf, I’d weave two short cowls – it’ll be summer time and people like short cowls in the summer.

So I wove one with the dark gray weft and one with the silver weft. This got me 4 finished pieces instead of 3. 🙂

I don’t think either of these photos show the cowls to their best advantage, but frankly didn’t want to go through the challenge of the Adobe process again with the other shots I’d taken.

Then I realized I’d finished weaving another scarf on my rigid heddle loom a few weeks ago but never did the finishing. This is the counterpart to the one shown here, this time with a dark purple chenille weft.

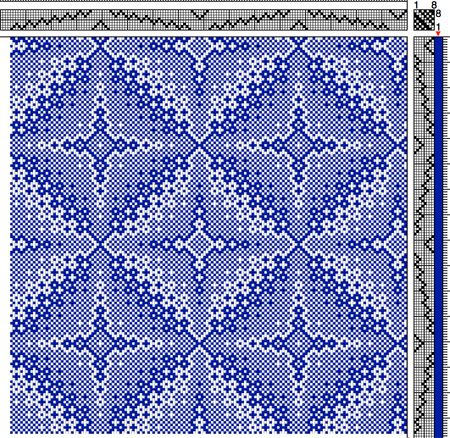

This rayon boucle warp doesn’t look good when double twisted, so I tried to put some beads on it to dress up an otherwise plain fringe. Geez, it was one problem after another, until I finally gave up, cut the fringe short-ish and called it good. So I ended December with 5 pieces. But absolutely nothing is on the loom now to start January. I saw a scarf woven from this to-die-for draft on Facebook and grabbed the draft from Handweaving.net – this is why I stay a member!

Thank you to Tara Oftenorth for creating this modification. I think I’ll warp my Macomber for this next.

UPDATES:

Jack had dental surgery last month – 14 teeth removed! Yikes! I suddenly realized that since his mouth has healed he has been doing a lot of chewing, much more than previously. Those teeth must have hurt, poor baby. So yesterday I went to Petco and bought 3 different kinds of chew toys. He loves them all. Hopefully this will protect future problems.

I googled the problem with Photoshop Elements, and was far from the only person with this issue. I followed directions for fixing it, and it worked like a charm.