A new mistake, that is. While I’m pretty good at not repeating my mistakes, I seem to be excellent at finding new ones to make.

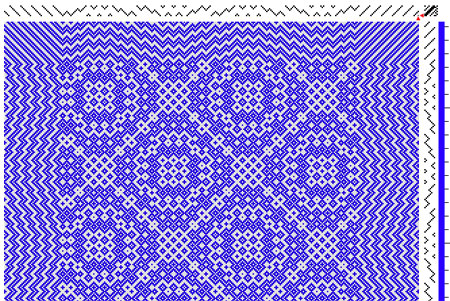

I wound the two remaining bouts for KC & CW’s baby wraps, spread it in the raddle, and beamed it. I started threading the heddles. All was going well. For about 1/3 of the width.

Then, uh-oh. What’s wrong? Where’s the gradient? I KNOW I did a gradient between each of the solid color areas. Where’s IS it?

Oh, CRAP! I beamed one of those bouts ‘backwards.’ What was on the left should be on the right and vice versa. Since both edges of the bout were fuschia, it was an easy – and awful – mistake to make.

What will I do now? Walk away from the loom for a bit while I ponder the situation. Here’s what I saw as options:

- Unwind the entire warp, flip the problem section, and re-beam. Unrealistic – at least not alone and without sufficient physical space. It would likely cause more problems than I already had.

- Measure out that bout again. Trash the offending section and re-beam on a supplementary warp beam. Since my Macomber doesn’t have a double back beam, this, too, was unrealistic. I know it CAN be done with a makeshift supplementary beam, but I’ve not done it successfully.

- Measure out the edges of that bout again and hang the re-measured threads individually from the back beam. Again, not realistic. Too many threads. I’d surely end up with lots of ends that were too lose and others that were too tight. And all tangled at the back.

- Insert a new set of lease sticks in the offending section, flip that section, and keep on threading. I liked that option. But the only way I could figure out how to insert a new set of lease sticks was to thread the whole section – 180 threads – then insert the sticks, unthread the heddles, and re-thread. That didn’t seem like a good use of time.

- Thread the rest of the warp from left to right – something I’d never done. Then remove the lease sticks from all but the offending section so I can flip it. That’s what I decided to do.

I have to say, threading from left to right was very ‘unnatural’ to me, and I was not at all efficient at it. But it got done.

So I slipped the lease sticks from the already-threaded sections of the loom, removed the raddle, and flipped the lease sticks.

Gee, look at the huge X of crossed threads at the back of the loom. Bigger in real life than it was going to be in my mind’s eye.

Hmmmmm. Well, the center of the bout – the solid turquoise section – was fine. That part didn’t need to be flipped. And the fewer ends that were crossed the less problem I’d be likely to have later on. So flip it back.

Now back to the front of the loom to thread those heddles. It still looks like quite the mess at the back of the loom.

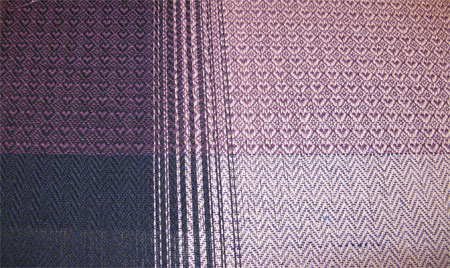

Here’s what I’m thinking…I’ll thread the reed. Then I’ll tie on to the front apron, being extra careful with my tension in that problem section. I expect I will have some problems down the road, but fortunately these wraps are average length, not the really long ones, and I always plan for plenty of extra warp length. So if I have to cut off after the first wrap and re-tie to the front apron, I can do that.

I hope that my plan works. If not……well, I’ll cross that bridge when I come to it.