The last few weeks have been crazy busy at my end. I was training the new executive director for Pfeiffer Nature Center – I’m now officially retired! YAY!! It was a great gig for me for 10 years – the longest I’ve ever had any job.

It also feels wonderful to be working only for myself now. I’d like to think that means slowing down some, but that won’t happen for at least the next several months. Lots of commitments. Still, I’ll be working on my schedule, from home, doing what I want to do – mostly. Every job has must-do tasks that are less than enjoyable. Laura Fry calls it administrivia, a term I rather like.

Meanwhile, I’ve been preparing for the first evening of the Community Weaving Project. It went GREAT, despite the fact that threat of thunderstorms made us change the venue to inside. I got men, women, and children to participate.

Of course, all were very successful. Weaving on a rigid heddle loom isn’t hard. At least not as long as someone else has warped the loom and is standing on the other side of it providing guidance and encouragement every step of the way. 😉

I even got Senator Cathy Young, who was on hand to share the glory of the Colonial Library’s 100th Anniversary (part of the evening), to weave.

This young man couldn’t wait for his turn at the loom. He already knits and crochets and was eager to try weaving.

In fact, he was so taken by the activity that he organized all my yarns after he was done!

Here’s a woman who’s part of my Fiber Arts Guild trying her hand at my LeClerc rigid heddle loom, which she said she much preferred to her Kromski Harp. She’s doing a hand-manipulated leno weave.

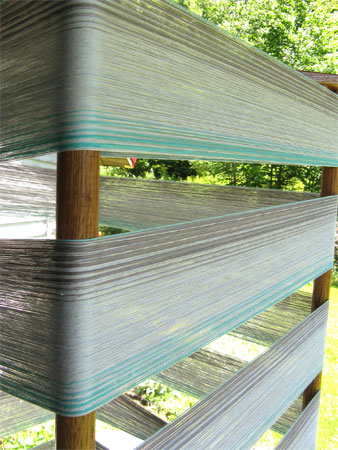

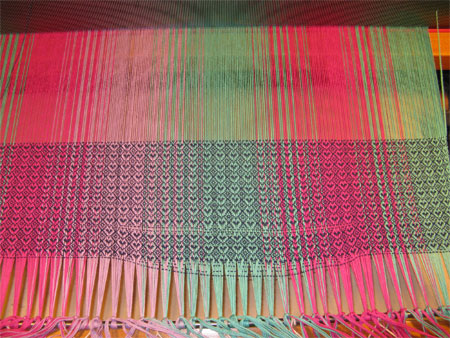

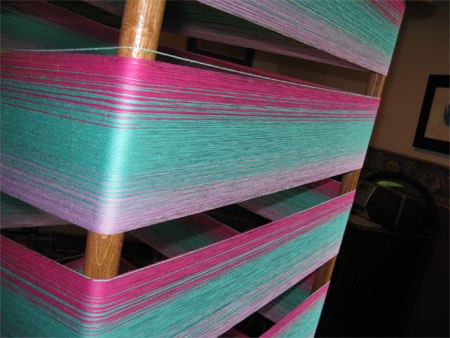

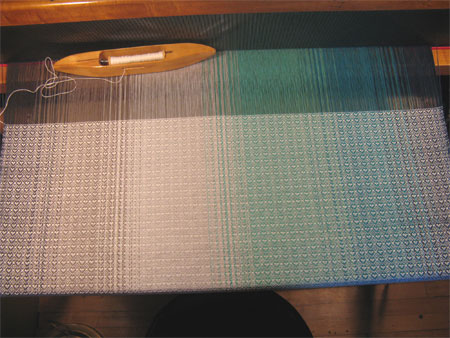

In between everything else I was doing, whenever I could find a few minutes I jumped to my Macomber to work on E&E’s custom baby wraps. EC has requested a few meters of hers with a cream weft and the rest with a marine. I’m working my way through the cream first. Although it looks rather dark in the photo, in real life it’s bright and cheerful. I really like it.

Today I’ll pick up a rental van, pack it, and head to East Aurora to set up for the Roycroft Summer Festival.

Whew! Maybe I can breathe next week?