After my success with my handmade semi-rigid heddle, I thought I was set for the real thing. Yes, the yarns were slightly different, but that shouldn’t present a particular problem. So I measured out the warp I intended to use, beamed it, and threaded it through my new ‘equipment.’

Then the trouble started. I couldn’t get decent sheds. Every single time I was fussing with the threads to get them to separate. Then I realized what the problem was…yarn fuzz.

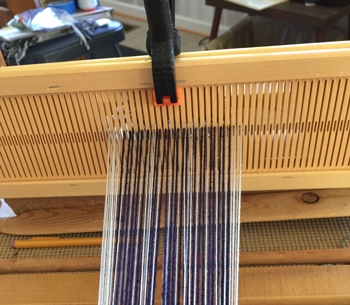

See the fuzz my arrow is pointing to? It was caused by the simple friction of the yarn, and it caused my string heddles to stick together. The yarns could not move up and down as needed, especially those that weren’t actually in the heddles but rather between them.

I pulled the fuzz out the best I could, but within a few passes of my shuttle they were all fuzzed up again. Clearly another fail. So I cut out the small amount of weaving I’d done and removed that homemade heddle.

There was only one possibility left: clamp together 2 rigid heddles so my threads would be sett closer together. If this didn’t work, I’d have to give up on the idea. I’ve only clamped 2 heddles together like this a few times before, and threading 2 rigid heddles is a bit tricky. Especially since for this weaving it isn’t a standard threading. But I went slowly and got it done.

Next was to weave up another logo.

I’d put painters tape on my front beam to keep the weaving at the width I believed I needed. But now since I was using 10/2 instead of 8/2 yarn, that 1.5″ was too wide. You can see that I narrowed the width as I wove. That was on purpose to see if I could make it more narrow, and if so, if it would look good. I thought it would work, but wanted to make one good logo before I fully committed to this demo. Allow me to present logo #10.

FINALLY!!! Now I can get back to weaving things for my upcoming shows!

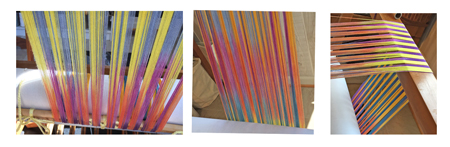

I did realize that there are some things you haven’t seen. So here are the finished pansies scarves. (Scroll down to see the pansies warp) First up is woven with fine dark purple weft, and I changed the direction of the curves at random along its length.

Same weft for the second scarf, but the treadling is all advancing, no curves.

Last I used a black weft. I only had enough length left for a cowl, but it’s plenty long for that. I used a regular repeat for the curves on this one.

I am happy with them and have gotten compliments, but I wonder if I would have liked them better if I’d left them in stripes instead of doing parallel threading, so that the colors would have stood on their own more. What do you think?

Eureka! You got it! I guess all that practice years ago with the Indian beading loom has paid off!!

They are awfully pretty scarves and you are an awfully persistent band weaver!

Thanks, Theresa. Persistence isn’t always helpful. As in this case. I spent TONS of time on this, and it won’t gain me a bit of money or much else. Just the satisfaction of conquering it.