This isn’t my first set of placemats, but it is my first use of a supplementary warp. I had to use my Macomber to achieve this, and although a fine loom, I still haven’t really gotten used to it. I don’t know that it will ever find the place in my heart that my little four-harness counterbalance has.

But that’s not what this post is about. It’s about placemats.

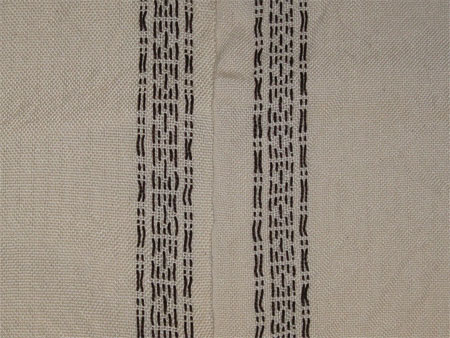

The majority of these handwoven placemats is a 5/2 pearl cotton in natural; the supplementary warp is a chocolate brown 3/2 pearl cotton. I sett them at 18 ends per inch, believing that would give me a nice, tight weave.

I know, I know, I should sample. But I don’t do it. My home ec teacher told me I should baste prior to machine stitching, and I don’t do that, either.

Beating with what I consider to be an average beat, I was not happy with the placemats — too loose, particularly the supplementary warp. That’s the one on the left. But I didn’t know that till I had a full placemat done. And by then I didn’t want to either (a) unweave an entire placemat and beat it more firmly, or (b) lose an entire placemat. I plan my warps pretty carefully and knew I’d warped enough for 8 placemats, not 9. So I continued with that set of 4.

Now I considered…should I resley to 20 ends per inch before I wove the next set of 4? If I did, I’d lose a bunch of width that would affect my finished size. Not what I really wanted to do. So I opted to beat really hard on every pass of the shuttle. Not my favorite thing to do, but a reasonable solution.

Then I decided I’d wet finish the first set of 4 in hot water in an attempt to tighten them up. It did tighten them up, but I still wasn’t completely satisfied – the floats in the supplementary warp are still too far apart.

After a nice hard press, I’m okay with both sets. Here they are, rolled in sets of 4.

I still like the tighter set better, and will definitely sett future placemats at 20 ends per inch. This is my version of sampling — deciding what I’ll do differently next time.

Your turn: do you always do things “the right” way?