All blacks are not created equal. Sometimes it’s the dye, sometimes it’s the base fiber, sometimes it’s…I don’t know what. I’m not sure how well it shows in the photo above, but I was finishing CT’s wrap, woven with custom dyed black cotton/hemp blend, and started TS’s wrap, woven with Maurice Brassard’s black cotton. In real life, the MB yarn is brighter and crisper than the the cotton/hemp yarn. In some fabrics I’ve purchased, the black seems to have a green base, and in others a red base. Is that true or just my perception? Beats me.

I think I mentioned that I’m considering working on my Certificate of Excellence (COE) with the Handweaver’s Guild of America. One of the exercises is to create a color wheel from yarn. I bought a styrofoam disk, found the center, and bored it out so I could wrap it with the yarn. As usual, the colors in the photo aren’t exactly the same as they are in real life. And the colors in real life aren’t perfect…I did the best I could. I used MB cotton except for the blue-violet section; there was nothing even close for that color. In the cottons, the worst ones are the red-orange and the yellow-orange; both have too much brown in them. I will explain that in my submission, if I go that far.

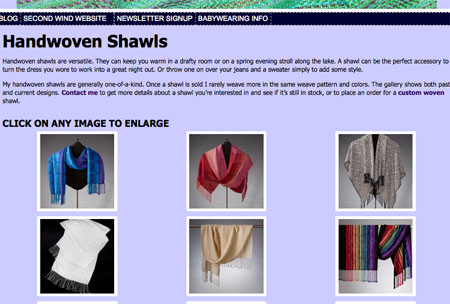

As a micro-business owner, there is an unending list of things to do. If the weaving were all that there was, I could get a lot more products made, but of course, the point is to sell them. And that requires everything from applying for and doing shows to marketing both locally and on the web. After beating my head against the wall several times with different approaches, I finally realized that I was making the rebuilding of my website harder than it needed to be. The reality is that I do very few sales directly from my website; its primary purpose is to keep me out there, a way for people to find me and to see examples of my work. Once I acknowledged that, it was easy to make the decision to use the same basis for my website as my blog — WordPress — and the same underlying theme. That way I’d have brand consistency, as well as software that was regularly updated and mobile friendly. I still have to build a few pages (Scarves and Other), and get more products on my Handwovens for the Home page, but I’ve made great progress and am satisfied with what I’ve done. Click on the links in the menu bar above and check it out.

You can do UPS online print and ship too. There’s and option to schedule pickup, or you can go to a drop box or store to leave the outgoing items.

Thanks for the tip, Amanda. I’ll have to check that out!

Good job on the sales site! I’ve just spent the last week packing up a bunch of weaving tools/books/items from my Dad’s studio that I’ve sold for him. What a pain in the neck. Shipping is the pits IMHO

Yarn just like fabric uses a number of different bases. Having done resist dying in the past I often find it interesting what is under the main color. You are spot on about either red or green bases for black. I find the green bases crisper.

Have you looked at Lunatic Fringe for some of those color gradients? Of course you were probably trying to pull from inventory and not have to buy anything.

You’re right, Theresa, I was trying to pull from my extensive stash. But since I use so many MB cottons I was willing to buy a cone of the other colors I needed…but they don’t have anything better than what I already have. Didn’t want to pay separate shipping to go to Lunatic Fringe.

Shipping, IMHO, is getting worse as the USPS services fall down while their costs increase. I may have to switch to a different carrier, and that will make shipping more of a PITA since I’ll have to take things somewhere to ship them. USPS picks up at my house. Although I will say that I’ve only done the online click & ship thing since I’ve lived in the city; when I was in the sticks I always took my boxes to the P.O. Can’t really say why…it was just what I did.