I’ve had a request to post a photo of the hand painted yarn I used for RGB’s wrap.

Once the yarn is wound from skein to ball, it’s really hard to see what the end result will be. I unwound a little, but still, there’s really no way to know how the colors will work across the width of a piece until you throw the shuttle. The way the colors will pool is dependent on several factors, most notably the length of the skein when painted, the number of dye colors used, and the width of the warp. All three have major impacts on the end result.

Now for the post I intended to write… I have finally found the time to cover my kitchen chairs with the fabric that I wove for this purpose. Like many (most?) things, it took a lot longer than I’d thought.

But first for some fun. My grandson was visiting the other day and we had a grand time playing Sushi Boy. I’d roll him up in the foam I’d purchased for chair padding, then he’d unroll himself. This caused peals of laughter every time. And requests to do it again. And again. And again. He’ll be disappointed next time he comes that the foam roll is gone. ;-(

So now for the work. Each of these chairs already had 3 layers of covering. Under the (ahem) lovely green vinyl was a blue woven fabric. I wish I knew correct terms…maybe this is called damask? I’m guessing it was scratchy in its youth.

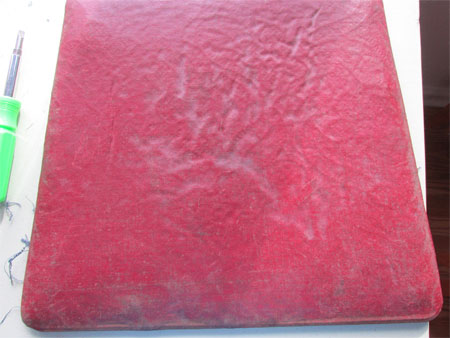

Under that was red cloth. Based on how deteriorated it was and how it ripped, I’m thinking that was oilcloth. Like all reds, the color is completely inaccurate in this photo…it was a nice, deep red.

Beneath the red was a layer of cotton batting used for padding. Amazingly, although the chairs were hard as rock with the 3 layers of cloth, by the time I got down to the cotton I could tell it still had some cushioning ability left!

Here’s why the process took so long: each of those layers of cloth had lots of brads holding it in place. I had to count on one of the chairs because otherwise I would have been accused of major exaggeration. In that chair there were 123 brads! I’m sure the number was similar in each of the other 3 chairs. That’s lots of (close to 500) brads to be individually removed.

So I got the brads off, cut the foam to size & shape, and stapled on my handwoven fabric, stretching tightly as I went. My corners aren’t as neat as a professional would make them, but I think they’re fine.

My overall reaction? I wish I’d woven more colorful fabric. As I looked at each chair individually and the 4 together, the word ‘staid’ kept entering my mind. These chairs look rather conservative for my personal tastes.

It remains to be seen how well the fabric will hold up. But I know now that if I need to weave more fabric, the weaving doesn’t take long, and since I’ll only have to remove one layer of fabric, held on with admittedly a lot of staples, it won’t take anywhere near as long to remove and replace the seat covers. And now I know that I need to be freer with my color and design choices.

Thank you so much for upping the variegated yarn sample 🙂

It still helps to choose for a potential next custom 🙂

Thanks, Ramona!

I really like the chairs!

And you KNOW I am always drawn to variegated yarns. How do they make it? If it is painted, how do they organize the project? Have you ever run into a video or explanation of how it is done?

If that one fabric was like a nylon loop or boucle making the pattern it could have been a “frise”.

Grand fun with the grand. Maybe you’ll have to keep a roll on hand. The chairs look so fresh though

even if they may not be the pop of color and excitement you wanted. As you said, you can always weave more and color combo lightening may hit at any time.

Oh – thanks for that terminology, Theresa! I wonder if I can remember it. 😉

I agree, changing the chair fabric will be a piece of cake next time…and there will likely be a next time. I like your phrase – color combo lightening – and will probably remember and use that.